Eulogy to a Hammerman

Eulogy To A Hammerman November 11, 2018

The forge shop on River Street has been demolished and the smaller hammer room at the Carriage Goods plant on Part Watson Street has been razed. The Brwer-Tichener Corp. office building is all that remains. Many Cortlandites remember the sound of their hammers that echoed across Cortland and Homer.

Becoming a hammer man was a destiny. Children on the east side expected to work there. They went to sleep with open windows listening to the crashing rhythm of ka-boom-clang-clang as the hammers hit down steadily from dawn until midnight. The deafening sounds lulled them to sleep.

Working at Brewer’s was a tradition. Fathers, brothers, uncles, nephews, and cousins worked at the forge shops. The side walls of the plants were all open. From River Street or inside the always open gates, kids could see their fathers working inside swinging steel from the furnaces to the hammers. The forge shops were a man’s world. No women worked in the hammer rooms. A few did work at jobs beyond the hammer room in the Carriage Goods plant..

Forge shop working conditions were harsh, almost brutal. The furnaces roared and spit out flashing tongues of flame across their 5 ft wide slots. Men kept the slots filled with heavy, long bars of steel which heated to a red hot glow at 2,450F, the forging temperature. They pulled hot bars from the furnace all day. Hammermen usually worked as singles on the “small side” which had hammers up to 2000 lbs. On the “big side”, from 3000 lbs. to 5000 lbs., they worked in crews of up to 4. One ran the hammer, one swabbed the dies with oil, two swung bars from the furnace to hammer then to the hot trim presses and back to the furnace. The hot forgings dropped in piles in front of the hammers and men with pitch forks bent and scooped them in to bins.

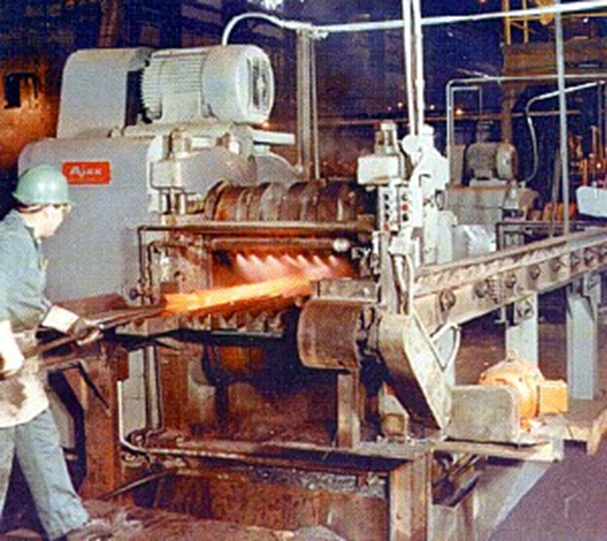

Hammermen also ran upsetters and rolling mills. Upsetters were massive horizontal hammers. The red hot bar were place in a giant clamp in the upsetter. The machine slammed shut on the bar as a 5000 lb ram slammed forward and squashed the hot steel into shape.

The rolling mills operated like a giant, powerful wringer washing machine. Two big steel rolls swirled at high speed and came together every few seconds to form a round slot. The dies tapered and elongated the bar. One end doubled length in a second as the operator held on. If he was out of sync with rhythm of the rolls, the bar would slam back and knocked him on his ass, hot bar and all. Only a few men had the agility to operate the rolling mill.

Hammer Room pay was based on time study, so to earn top dollar, the men worked as a team to make every hammer blow count. The fast tempo was kept up all day.

Their work was hazardous. One moment of carelessness could cost two fingers. Too often, it did. A hammer ram would fall on a hand, or fingers would be caught in the upsetter. In later years, they would hold up a hand showing only two fingers as a sign of having worked in the hammer room. Molten steel could drip off a bar in to a boot. It did on my father. Many hammer room workers had their hearing damaged. Some were hit with flying steel parts that vibrated lose and flew about. They wore burlap aprons to protect their privates. Despite their ruggedness, some men broke down mentally and literally had to be wrestled down and pulled out of the hammer rooms before hurting anyone. The insurance company treated their injuries as routine and simply issued a chart listing the compensation for lost eyes and limbs. An eye was worth $2,000. The accident rate improved in the 1960’s when helmets replaced leather caps and ear muffs replaced wads of cotton in the ears.

They worked through rough conditions . The noise level in the hammer room was 100+ decibels. Communication was an occasional shout under a raised ear muff, followed by a nod. High pressure air screeched constantly past the hammerman to blast scale off the dies. Sparks, scale, oil, and smoke flew through the air constantly. Men were blackened from head to toe in the first half hour of each day’s work. Despite the roaring furnaces, the temperatures in the winter were as cold inside the hammer room as outside. Men were seared on their front side while icicles formed on the back sides of their clothes.

The hammer rooms were tall, all-steel construction. Originally built with many windows so as to use natural light. the windows had all shattered out decades ago from flying scrap and vibration. Despite the winter temperatures in Cortland, there was never a heating system installed in the hammer rooms. On some frigid winter mornings, men would climb up their hammer, douse it with flammable naptha, then light it to thaw it out.

Even their downtime was rough. They briefly had a hot lunch service, but the Cortland Health Dept shut it down in a thoughtless contribution to industrial hygiene. That left working men carrying hot steel having just crackers, a cigarette and coffee for lunch. Even the men’s room was crude; it was as black as the inside of a coal mine. It one dim light bulb. The urinal was a length of pipe drizzling water down a wall.

The men endured because the pay was good and the work proud. They called the process “hopping bells” as they forged bell-shaped fittings for high voltage power lines. These forgings electrified rural America. Each bell had a hammerman’s initials proudly forged in to it. They forged construction hooks used to build skyscrapers, and Otis Elevator bolts to hold up elevators, landing gear for P-51 Musangs, and parts for every war from WWI to Vietnam. Lives depended on their their work.

Despite the heat, the cold, the noise, the smoke, and the arduous work, this work fulfilled a destiny. They were men of steel. When God was looking for another hammerman and crew, He found them in Cortland at the forge shops.

Ka-boom-clang-clang.

PS: We remember their names: Ardis, Argyle, Arnold, Bordwell, Branagan, Brown, Burnham, Bush, Canillis ,Carmen, Carr, Casidy, Casterline, Caughey, Congdon, Conway, Coon, Costello, Davenport, Dawson, Dehbein, Dillenbeck, Drake, Fox, Funkhouser, Goodale, Greenfield, Gulini, Hall, Hilsinger, Hopkins, Macomber, Marks, Marshall, McCoy, Morris, Murphy, Neville, Nichols, Olmstead, Ostrander, Packard, Randall, Rawson, Rosato, Sorrels, Stevens, Strack, Turner, Warner, Washington, Woods; and more.

PSS The post titled BEYOND THE HAMMER ROOM describes other work at the forge plants.

PSS: Here are some of the hundreds of comments posted in Cortland Reminisces:

Rose Marie Van Dee What a great commentary I really enjoyed reading it. As a teenager I would walk down River street and the sound of the hammers were so loud they terrified me by the force , heaviness of the slamming hammers. I could never imagine what it was like inside that factory until your story. Thank you.

Cheryl Morse We sure went to sleep at night to the sound of those hammers banging.

Lois Waffner Heard them down on Bement Place. Friend John Hudson worked there.

Lynn Stoll The men of steel helped to put cortland on the map, along with Brockways, SCM, overhead dr, crescent corset, Thompson boat, Wilson’s, cristal craft, wickwires, and many farms that delivered milk to your back dr and so many more!!!! Cortland was a great place to grow up in.😊 AKA..Mike Dexter!!

· Reply ·

Allan C. Ardis Cortland was a powerhouse of industry throughout the mid-century. Luckily, I was part of it then.

Lynn Stoll Growing up on Cedar St. friends would visit and ask what the loud noises were and of coarse the response would be What loud noise? They became part of the every day sounds of the neighborhood along with the daily train whistles 🤗

Denny Rankin Loved this, grew up with the River St. factory in my back yard. My grandfather ( William Brangan) worked there as a machinist I believe. I used to visit him in the summer on his lunch break since he sat out on the East Garfield side. Good memories.

· Reply · Allan C. Ardis Yes, precision machining for the forgings was important and made BTC the most respected company in the industry.

Debbie Crandall Heath Lot of those men developed alIzhimers in later year S because of all the metal they were exposed to.

Patti Dintino Was sorry to not see my Dad’s last name included (Conway), I did see a whole lot of others names that I did recognize tho!

Allan C. Ardis Patti Dintino It’s there now.

Patti Dintino No problem, I don’t know how you remembered as much as you did here!😉 Many thanks for adding him in this comment.

Chris Contento Nice

Gail Ventura I could hear the hammers at my Aunt Gertrudes home on Rt. 11 near Blodgett Mills. Like the steady beat of the heart. They echoed down the valley.

Gail Ventura I have an ironing board made by Brewer Tichener, very heavy , sfill use it. Label intact, probably made just before World War 11. I imagine would have not been made during war time.

· Reply Allan C. Ardis Made at the Carriage Goods plant on Port Watson Street. THey did a lot of heavy sheet metal work, including very good folding office chairs. If you watch Pawn Stars on the History Channel, that ironing board would be the type of thing that they would buy.

Gail Ventura I think I will keep it. Around 75 years old. Let the next generation deal with it. Lol. It is very heavy.

Connie French My mom Gloria Peppingloria did that till she retired

Gerrie Marshall We lived on Tioughnioga Ave and heard the hammers day and night. My Uncle Vern Morris worked there for years.

Doug Burnham Jr. Both of my grandfathers worked there ! Francis Burnham and Robert Neville

Allan C. Ardis Fran and Betty Burnham lived directly across the street from us on River St. Steve Burnham, your uncle, was my age and a childhood friend. Dougie, your father, was a couple years older..

Barry Ardis Hello Doug, My name is Barry Ardis I also lived on River street. Your Aunt Marsha was my first love. I loved Shirley, Charlotte, Steve and your father we were all like family. This is a picture of me and Shirley from around 1965 or so. Please say hello to your father I do hope he’s well.

Charlene Prosser Thanks for the commentary. I worked at the River St Agway in the early ’70s and remember the sound of those hammers. Thanks again!

· Reply · Allan C. Ardis I was a young engineer. I crossed on to the Agway property monthly to check the outflow of water from the forging plant in to the river.

Allan C. Ardis I knew Fran Burnham and his family. I also knew Ralph Nichols at BTC

Renee Burnham Allan C. Ardis yes Fran is my husband grandfather and Ralph was my Stepfather, and Robert Neville was my husband grandfather also…

Robert Argyle Jr. Very cool pics. Brings back memories. We lived at 46 1/2 River St. The house is gone now but the garage my dad built is still there. He ran a hammer for 22 yrs.

Allan C. Ardis My father Clarence and he were close friends. Pop spoke of “Argyle” often.

Christopher Phalen I started working there in the late 80’s in the hammer room. Your comment about the working conditions was right on. I’m sure a lot also improved, but yes it was a dangerous place to work. Thankfully I still have all 10 fingers and 10 toes!

Cathie Bisha Jon Trembley I thought you might be interested

Allan C. Ardis I am interested, but tell me more. Memories need strengtheing.

Charlotte Sunderland Sonny Carmen lost use for his fingers after a hammer or something fell on his hand his name Clifford Carmen worked there in the late 50 til 70s

Cathie Bisha Thank you for sharing.

Paul McCoy My uncle worked there – Lee Goodale.

Allan C. Ardis I almost remember Lee Goodale. Help me out. What years? What department?

Paul McCoy Allan he was in the forge area and hammer shop. I think it was in the 70’s. He didn’t talk much about it. Too late to ask him now as he passed away a white ago and his wife passed two years ago.

Robin Metcalf Thanks for sharing Allan….it helps people to understand what the “hammers” and Brewers was all about. It was apart of my growing up yrs with my Brother-in-law Vern Marshall working there.

Thanks again…so glad your here to post some history of Cortland

Allan C. Ardis I knew Vern. Good man, on Hammer Maintenance, a dangerous job.

George Clancy My GRANDFATHER worked at BTC.. Vim Belknap. Not too sure of what he did there… but he could hear worth a crap in his retirement years.

Thomas Brown Henry Rehbein

Deborah Coats Ward Ellsworth

Kevin Walsh We have a Brewers exhibit at the CNY Living History Center. Can I use your Eulogy in our exhibit?? This says so much more than any of us could.

· Reply Allan C. Ardis Yes, you may. I’ll send you a slightly updated Rev 2 of the narrative in messenger right now. Use either version. Many thanks. Allan C. Ardis

Kevin Walsh Allan C. Ardis THANK YOU Sir

Paula J Marshall-Riese Jandrews and Arnold too

Cheryl Morse Kevin, I am Allan’s sister. I am sure he will be glad to have this Eulogy read by one and all. It is a unique story and is appreciated by everyone who reads it.

Kevin Walsh Thank You very much. Our folks at the museum know that Brewers was a tough place to work, but to have a description of it written by someone who worked there is priceless. Thanks.

Martin Petrella Nice post for those of us who had no idea wgat went on there. Thank you for sharing.

Becky Drake-Nowalk My father Wayne Drake worked there too. He was one of the unfortunate ones to lose fingers and part of his hand

Allan C. Ardis Sorry to learn that. As the post says, it happened too often, and there was not enough sympathy at the time.

Ann Casey I worked in the Engineering office before Joslyn bought BTC. Never will forget the hammers the heat of the forge and the great people who worked there.

· Reply · Allan C. Ardis Ann CaseyWe must have known each other. I worked in the Engineering Dept, too. From 1969-1973 for Bill Harrison at the Forge Plant, then from 1974-1976 at the Carriage Goods/Finishing plant, working for Hus Anthony.

Ann Casey Allan C. Ardis I was there mid-70’s then after the buy out (and finished my assignment) transferred to Port Watson in Purchasing. Rocky Roe was my boss. And 2 other men who trained my well. I’m bad at name recalls so I can’t say their names but if reminded…maybe.

Allan C. Ardis Renee Burnham Ralph Nichols was an intelligent and active fellow. He was head of the BTC Fire Brigade. I was on the Brigade, and wrote their monthly meeting minutes. The Chief Engineer, my boss, said the BTC Fire Brigade was the best he had ever seen.

Donald B. Hobart Great post! Had many friends and relatives that worked there over the years. One cousin, Merrill Randall lost three fingers in the hammer room. But you would hardly know it. He continued to work well with just his thumb and index finger.

Melony Marks-Coville A friend of mines father worked there, Clifford Hopkins

· Reply

Allan C. Ardis I knew “Hoppy”. He was a big and friendly fellow.

Mike Lyman Well written. My late father in law Bill Brangan worked there for many years.

· Reply ·

Allan C. Ardis Do you know what department?

Mike Lyman Allan C. Ardis I know he ran a break press.

Clyde Rice Frank Willam sr

Dorleen Atchison Absolutely wonderful writing about an important piece of history!

As kids we would come into town from Killawog and listen for the sounds of the forge. I had no idea what the sounds signified. I am in awe.

Allan C. Ardis Dorleen AtchisonIn the search box on the left, type in HAMMER ROOM DESTINY. It will pull up a video posting of the hammers in motion and sound. Make sure to click the sound icon to turn on the sound. Let me know. Thanks!

Cherri Carter Fellows My fathers hearing was horrible from working there for so many years. He once fell from a ladder 60′ and broke his back at work, his hands were a mess all cracked and sore for years and years even had to see special drs in Syracuse and Ithaca for them, as did others I knew there.

Charlotte Sunderland this is charlotte falso Sunderland I knew u

Suzan D’Ippolito That’s how I knew it was time to get up as a small child. My brother would walk us to Pomeroy school or Dexter park and I remember thinking why don’t they fix the broken windows. The hammers constant clang just seemed so normal. My mother worked at the Port Watson Street office and became one of the first computer programmers there.

Allan C. Ardis I knew Mrs. D’Appolito. If she is still alive, possibly she will remember me. Here’s a photo that I took for a BTC news release about 1975.

Suzan D’Ippolito Allan C. Ardis Yes, she is very alive and well. Retired from Cooper Tools in Apex, NC which she transferred to after BTC. I will show her this. Thank you for your knowledge and stories of BTC.

Barbara Young I had relatives who worked there . Was so sad to hear it closed.

Reply · Allan C. Ardis What were their names? What time period? Did you see my Eulogy to Hammermen? It was a tribute to all those who worked there, and I would like to make sure that their names are included. attention: Barbara Young

Donna Jenney My stepfather worked there for years

· Reply ·Allan C. Ardis What was his name? What time period?

Donna Jenney Tom Ardis, he retired in mid-late 90’s

Charlotte Sunderland please do not forget to add clifford carmen aka sonny to u list of people who were injured there

Allan C. Ardis Charlotte Sunderland Will do, in next posting of it.

Marsha A Thorp my cousin Andy Barber worked there..

Allan C. Ardis What time period, Marsha?

Ivan Angell In the mid 70’s I worked in the drill & grinding rooms on River St and the galvanizing room on Port Watson. Great experience. Also a neighbor Gid Meacham worked in the River St office.

Allan C. Ardis Ivan Angell Interesting. I worked at both plants as a young engineer 1969-1976. Gid Meachem was Safety Director and a pretty good guy. Gid had started out working in the shop, then became the union president, then was promoted in to management.

· Reply · Ivan Angell Allan C. Ardis Gid got me the job at BTC full knowing that I would be there for only about a year. Was an experience that I was grateful to have had in my 20’s and will always have fond memories of.

Deborah Bolton Monty Awesome history. Thanks for the information. There should be more of this!!

· Reply Allan C. Ardis indeed, there is more. To view them, in the search box on the left, type is FORGE or HAMMER or Allan Ardis. THey’ll come up.

Deborah Bolton Monty I worked at the JM Murray Center on 281 in the sales office and also doing home estimates for the residential upholstery and stripping and refinishing. My office was in the Camp Building. I heard lots of stories of the slaughterhouse that building used to be!! Anyone have stories?? I see that the Camp Building has been torn down..

· Reply · Allan C. Ardis Deborah Bolton Monty Yes, I recall a major slaughterhouse bad meat scandal at that location back in about 1960. I was only a boy, but everyone was talking about it at that the time. They were closed down, at least temporarily.

Deborah Bolton Monty I didn’t move to Homer until summer 1968 so I don’t know anything first hand about that place. i only was told stories about the slaughterhouse. It grossed me out to work there after hearing those things.

Paula J Marshall-Riese Love reading all the remarks, so many memories, so many family and friends worked there, I know I put some other names Uncle Jim Marks, so many Marshall’s, all three brothers at one time Ron, Jim, Tim, Ron retired when they closed,Dick Arnold, Kathy and Harold J Andrews, worked at SCM for 25 years would love some pics from there too.

Dale Seymour My fathers Uncle, Don Nightingale worked and retired from Brewers. My dad also worked there – Hank Seymour.

Pierre Beaudry Listened to the hammer for 30 years great respect for the folks that worked there, Dennis Caughey And TerryOstrandet come to mind too..

Pierre Beaudry sorry Trisha Ostrander Space Carol Dodge Ostrander

Trisha Ostrander Space What a cool article! Yes, my dad was in the hammer room for most of his life. I know there is a pretty cool black and white picture of him in there. I’ll have to see if one of us has it.

Terry Ostrander, Amy Ostrander

· Reply Allan C. Ardis I hope you’ve seen my other posts on the hammer room, including Forge Shop Christmas Miracle that was just reposted. If not, go the search box on the left and search on FORGE or HAMMER or my name. Kaboom Clang Clang.Allan C. Ardis

Christine DeMond Marshall Yordy Tim Marshall only 17 years old, how he brought Jody into the world

· Reply · Allan C. Ardis Christine Christine DeMond Marshall YordyGood to know. Going back in family history, several Marshalls worked at the forging plant on River St. Could you let me know which ones you and TIm were related to? THanks!

Christine DeMond Marshall Yordy Almost all his uncles and brother Ron Hall

Post 2

EULOGY FOR A HAMMER MAN, STEPHEN RANDALL ARDIS

From childhood through life and until our last conversation 2 weeks ago, my brother Steve spoke of his passion to be a “hammer man” in the forging shop at Brewer-Titchener Corp. in Cortland, NY. As children, we slept in the same room together, about a block away from the forge shop hammer room on River Street. Each night, we went to sleep listening to the metal-on-metal crashing rhythm of ka-boom-clang-clang as the hammers hit down steadily until midnight.

In1963, we moved to SC. In about 1969, both of us moved back to Cortland and went to work at Brewer Titchener Corp. (BTC). In doing so, we joined the family tradition. Our father Clarence and uncles Kaiser, Charlie, Herman, and Wayne, and cousins Tom and Carl all worked at Brewer’s. The hammer rooms was a man’s world. It was almost like being in combat. The furnaces roared and spit out 2-foot tongues of flame across their 5 ft wide slots. The slots were kept filled with heavy, long bars of steel heated to a red hot glow at 2,650 F. That was the forging temperature. Only a strong, conditioned man like Steve could pull hot bars from the furnace all day and hold them on the hammer dies as they were pounded in to shape by 3000 lb, 4000, and 5000 lb hammer rams. One second of carelessness, and he could lose two fingers. It happened so often that we kiddingly held up our hands with only two fingers showing as a sign of the hammer room. The noise and vibration from 30 hammers running was incessant. They had a rhythm. When not running a hammer, Steve was one of the few men in the hammer room that could operate the rolling mill, which operated like a giant, powerful wringer washing machine. Two massive rolls came together every few seconds. Red hot bars were inserted in to the rolling dies coming at you. The rolling mill was spinning at high speed. If the hot bar missed the die, it was slammed back at the operator and knocked him on his ass, hot bar and all. Steve didn’t miss. The noise level in the hammer room was a 100 decibel din all day. Sparks and smoke flew 10 feet in to the air all day from all the hammers. Men were blackened with flying oil and soot. Despite the roaring furnaces, the temperature in the New York winter were as cold in the hammer room as outside it. The hammer rooms were tall, all-steel construction. The windows had all shattered out decades ago from flying scrap and vibration. Despite the heat, the cold, the noise, the smoke, and the arduous work, Steve loved his work! It fulfilled a destiny for him. We spoke of it in almost every conversation over a 50 year time span.

If God is looking for a good Hammer Man, He now has the best one.

The hammer sound ka-boom-clang-clang goes on in Heaven for Steve.,

Allan C. Ardis